GOST 24392-80

GOST 24392−80

INTERSTATE STANDARD

SILICON AND GERMANIUM SINGLE CRYSTAL

MEASUREMENT OF ELECTRICAL RESISTIVITY BY FOUR-PROBE METHOD

Edition official

BZ 10−99

IPK PUBLISHING house of STANDARDS, Moscow

UDC 669.782/.783−172:621.317.33:006.354 Group B59

INTERSTATE STANDARD

SILICON AND GERMANIUM SINGLE CRYSTAL AND CESKY E

GOST

And).mereia electrical resistivity 1 1

four solovem the metol 24392−80

Monocrystalline silicon and germanium.

Measurement of the electrical resistivity by the lour-probe method

AXTU 1770

Date of the air force.1СНМЯ 01.01.81

This standard sets by four-probe method of measuring resistivity on a flat surface of ingots of monocrystalline silicon and germanium electron or hole type of conductivity in the range of values of the electrical resistivity of the MO-4 Ohm cm to 1 10* Ohm cm

The method is based on measuring the potential difference between two probes by four-probe measuring head installed on the surface of controlled shape, by passing an electric current of a certain magnitude through the other two point probes located on the same surface, and the calculation of electrical resistivity.

(Changed edition, Rev. No. 2).

I. EQUIPMENT AND MATERIALS

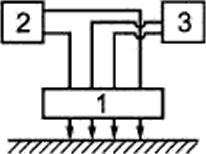

Block diagram of measuring installation is shown in Fig.

|

| 4 |

/ odd iresolve the credentials of the goal and he CA: 2 — source Pasyuk who soundboard:

3 — a device for the purpose of electrical voltage: 4 — sample

Measure.Tina the unit must be certified for accuracy of measurement of the specific electrical resistance not exceeding 5%.

1.1. Measurement by four-probe head with four linearly arranged probes of tungsten carbide shall conform to the requirements given in table. 1.

Table 1

| The nominal value magundayao distance cm | Permissible deviation magundayao distance. % | The pressing force of Zoila F. N | Lipany the size of the working plachecki probe, µm, not more |

| 0,159 | |||

| 0.130 | 11 | 0.50−2.00 | 60 |

| 0.075 | |||

| Edition official | Reprint prohibited |

© Standards publishing house. 1980 £>, And P. K. Publishing house standards. 2001

C. 2 GOST 24392−80

1.2. A constant current source, ensuring the creation in the measurement circuit an electric current of variable polarity, must meet the requirements given in table. 2. Table 2

| The upper limit and «measure specific elegicheskogo resistance R. Ohm cm | Srnn limit of electric current. And | The upper limit of the measured electric voltage V, In | Input electric resistance measuring device of Lm. Ohm, not less |

| -3 | 1,010-' | 2,1 10-1 | 1I03 |

| 1 10-g | 1,010-' | 2,1−10-3 | MO4 |

| 1−10-« | 1,010' | 2.1 10-3 | 1 101 |

| 1 10° | 8,2 10~2 | Koyu-' | MO6 |

| I101 | The 8.2 10-3 | 1,010-' | Ы0T |

| MO2 | 8,2−10-4 | 1,010-' | 110* |

| AT3 | 8,2 10* | 1,010-' | 2−10* |

| MO* | 8,2−10-6 | 1,010-' | at9 |

1.2.1. Admissible instability of the electric current during a measurement must be not more than 0.5%.

1.2.2. The error of measurement of electric current — not more than 0.5%.

1.3. A device for measuring electrical voltage with an error of not more than 1% should meet the requirements given in table. 2.

1.4. The insulation resistance measuring circuit should not be less than the input resistance of the measuring device.

1.5. Assistive devices and materials

Thermometer with a measuring error of not more than 0.5 ° C.

Abrasive materials according to GOST 3647.

Diamond tools with the use of diamond powders according to GOST 9206.

The diamond powders.

Filter paper according to GOST 12026.

The blotting paper.

At calico bleached GOST 2929S.

Material cleaning and packaging, fabric art. Or 6313 6304.

Drinking water according to GOST 2874*.

Ethyl alcohol according to GOST 18300.

Use tools and materials that are not inferior to the above in its characteristics and quality.

2. PREPARATION OF SAMPLES AND CONDITIONS OF MEASUREMENT

2.1. The measurements were carried out on flat surfaces with the roughness parameter Ra according to GOST 2789 not more than 2.5 µm. Measurement of resistivity silicon p-type conductivity with p more than 10J Ω cm is carried out on flat surfaces with the roughness parameter R. in the range (20

2.1. G To ensure the required roughness of the surface shaped grind abrasive materials or structures with the use of diamond powders.

2.1.2. After polishing, samples were washed with running potable or purified technical water, dried filter (blotting) paper or other materials and degreased with alcohol.

2.2. When measuring the distance between the edge (boundary plane) and the closest probe should not be less than 4 /0, where /0 is the nominal value meisongbei distance.

2.3. In the measurement of electrical resistivity by forming of the ingot width measuring track must be at least 6 /0.

2.4. Measurements are performed at a fixed temperature (23±2) 'C. the Controlled shape is brought to a temperature at which to conduct measurements. Carrying out measurement-

1

On the territory of the Russian Federation GOST R 51232−98.

GOST 24392−80 C. 3

tions at a fixed with an accuracy of ±0.5 ° C temperature range (23±5) «, performing temperature compensation of the measurement results in accordance with the application.

2.5. Measuring resistivity in Germany with more than 45 R Omsm and silicon with p more than 200 Ohm cm is performed by the darkening of the sample. For other ranges of electrical resistivity of the samples allowed the illumination of ambient light 500 Lux.

3. CONDUCT THE MEASUREMENT AND PROCESSING OF RESULTS

3.1. On the surface of the sample installed in the holder, gently lower the probes of the measuring head perpendicular to the surface.

3.2. Through the sample pass the electrical current / and a measured value of the difference between potenciacion internal potential probes at two polarities of the electric current. For the measurement of the potential difference U be the arithmetic mean of the obtained values. The value of the electric current is adjusted in accordance with the requirements of the table. 2.

3.3. Calculate the value of specific electric resistance R, Ohm cm according to the formula (1)

where U is the value of the potential difference. In:

/- the value of the electric current, which made the measurement. L;

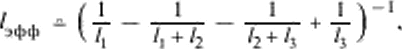

/, FF is the effective value meisongbei distances calculated according to formula (2)

(2)

where /, /2, /3 — the distance between the first and second, second and third, third and fourth probes

respectively.

When used by four-probe head in which the deviation meisongbei distance from the nominal value /0 does not exceed ±1%, in the formula (2) substitute the value of / = /0.

3.4. Carrying out measurements and processing of results with the use of automation according to the algorithm described in this standard.

Sec. 1−3. (Changed edition, Rev. No. 2).

4. PRESENTATION OF THE RESULTS OF MEASUREMENTS AND STANDARDS ON ACCURACY METRICS

4.1. The result of measurement of the specific electric soprotivlenie assetsa value calculated by the formula (I).

4.2. The random component of error of measurement of the specific electrical sopradele-tion characterizing sharemost of measurement results does not exceed ±2% at confidence probability P = 0.95.

4.3. The total measurement error does not exceed ±5% in the control samples with p<103 Ohm cm and does not exceed ±8% in the control samples with a specific electrical resistance of more than 103 Ω cm at a confidence probability P = 0.95.

4.4. The result of the measurement of electrical resistivity predstavljajut three-digit number if the first digit are 1, 2, 3, and double-digit, if first digit is 3 more.

Sec. 4. (Introduced later. Izm. No. 2).

C. 4 GOST 24392−80

APP

Mandatory

The result of the measurement of the electrical resistivity lead to temperature ^ = 23 'With the formula

RG (3)

0 *! — S (/-%)'

where R — electrical resistivity. Ohm cm;

— Temperature coefficient (tab. 1, 2);

/ — nominal temperature in the range of (23±5) 4 C; R, — erschrecken specific resistance at 23 'C. g*

The result of the measurement of electrical resistivity can be reduced to the nominal temperature within range (23±5) «, P

Table I

| Coeffiient temperature for silicon | Iseral electrical resistivity | on with p in | |||||

| 0.0001 -0.004 | 0.004 — 0.04 | 0.04−0.1 | 0.1−1.0 | 1.0−10.0 | 10,0−10000 | ||

l-type, 1/deg |

0,002 | 0.001 | 0.004 | 0.006 | 0.008 | 0.008 | |

p-type, 1/deg |

0.001 | 0.001 | 0,003 | 0,006 | 0,008 | 0.009 | |

TableA 2

| Dmier: Purna to >Fijian ■ for Germany | Iseral electrical resistivity. | Ohm cm | |||||

| 0.0001−0.001 | 0.001−0.01 | 0.01−0.1 | 0.1−1.0 | 1.0−10 | 10−100 | ||

| I-type, 1/deg | 0,002 | 0,001 | 0,004 | 0.006 | 0.006 | 0.006 | |

| p-type, 1/deg | 0,002 | 0.002 | 0,004 | 0,007 | 0,008 | 0.008 | |

APP. (Changed edition, Rev. No. 2).

GOST 24392−80 C. 5

INFORMATION E DATA

1. DEVELOPED AND INTRODUCED by the Ministry of metallurgy of the USSR

2. APPROVED AND put INTO EFFECT by Decision of the USSR State Committee for standards from

3. GOST 24392−80 complies ST SEV 1250−78

4. INTRODUCED FOR THE FIRST TIME

5. REFERENCE NORMATIVE AND TECHNICAL DOCUMENTS

| Obshchem NTD. on that given link | Item number | Obsecene NTD. nm which Lama link | Item number |

| GOST 2789−73 | 2.1 | GOST 12026−76 | 1.5 |

| GOST 2874−82 | 1.5 | GOST 18300−87 | 1.5 |

| GOST 3647−80 | 1.5 | GOST 29298−92 | 1.5 |

| GOST 9206−80 | 1.5 |

6. Limitation of actions taken by the Protocol)' No. 5−94 of the Interstate Council, but the standardization. Metrology and certification (ICC 11−12−94)

7. EDITION (March 2001) with Amendments Nos. I, 2, approved in may 1985; nurse, 1990 (IUS 8−85, 10−90)

Editor T. P. Sahipa Technical editor L. L. Gusha Corrector V. E. Nesterov DTP L. A. Circular

Over. N.: 1)2354 1−1.07.2000. Put in a set

Uch.*ITL. I. 0,50. Circulation 117 W. With 816. Zach. 455.

IPK Publishing house of standards, 107076. Moscow. Kolodezny… 14.

Nordio, and Publishing on PC Branch of IPK And tatslotto standards — type. «Moscow printer*. 103062. Moscow. Lyalin per. 6.

PCR 0S0I02