TU 14-4-775-76

USSR MINISTRY OF FERROUS METALLURGY

UDC 669.14-426 Group B 72 I APPROVE: Chief Engineer of the VPO Unionmetiz of the Ministry Ferrous metallurgy of the USSR V.I. Orinichev December 21, 1976 |

STEEL WIRE

HIGH-PURITY CARBON STEEL

METAL

Technical conditions

TU 14-4-775-76

(Replaces TU 14-4-570-74)

Date of introduction: 01.03.77 For the term: 01.03.82

AGREED: Chief Engineer of MMMZ S.M. Petrik December 21, 1976 Chief Engineer of NIIMETIZ K.I. Tulenkov "7" 10 1976 |

DEVELOPED BY: Chief Engineer of BMK V.K. Likhov " " 1976 |

1976

These technical conditions apply to high-carbon steel wire made of especially pure metal, used as a core in the manufacture of bimetallic wire.

1. ASSORTMENT

1.1. Nominal wire diameter - 1.4 mm.

1.2. Permissible deviations in diameter in a batch are ±0.02 mm, and in a spool should not exceed 0.02 mm. Wire ovality should not exceed half the diameter tolerance /0.01 mm/.

2. TECHNICAL REQUIREMENTS

2.1. The wire must be made from wire rod supplied according to TU 14-4-4-71, the chemical composition must correspond to Table 1.

2.2. The wire is supplied heat-treated with an etched surface.

On the surface of the wire after heat treatment and etching there should be no unetched or leaded areas, cracks, films, overlaps, delaminations, cavities, limescale, or oil stains.

The presence of marks, scratches, nicks and other mechanical damages with a depth of no more than 0.01 mm, as well as a layer of rust that can be easily wiped off with a rag, is allowed on the surface of the wire.

2.3. The mechanical properties of the wire must meet the following requirements:

tensile strength 137-147 kgf/mm²;

By agreement of the parties, delivery of wire with a tensile strength of 141-151 kgf/mm² is permitted.

The variation in the temporary tensile strength of the wire on the spool is allowed to be no more than 8 kgf/mm².

2.4. The microstructure of the wire should be sorbitol or sorbitol with

2

the presence of areas of lamellar pearlite and ferrite not exceeding those indicated on the photo standards given in Appendix 1.

Table 1

| Steel grade | Content of elements, % | |||||||

| C | Mn | Si | S | P | Cu | Ni | Cr | |

| no more | ||||||||

| BP5-Sh | 0.85-0.93 | 0.20-0.60 | 0.20-0.37 | 0,015 | 0,015 | 0.05 | 0.05 | 0.05 |

NOTE: Phosphorus content up to 0.020% is allowed, while the sulfur content and

phosphorus should not be more than 0.030%.

2.5. The depth of the decarburized layer on the surface of the wire should not exceed 1% of the wire diameter.

2.6. The wire is supplied on spools with a capacity of 250 kg, manufactured according to drawing No. 1295-UP-0. The winding must be even, tight, without loops.

2.7. The spool must contain no more than three pieces of wire weighing at least 30 kg each.

2.8. The supplier must guarantee that the supplied wire complies with the requirements of these technical specifications.

3. ACCEPTANCE RULES AND TEST METHODS

3.1. Wire is presented for acceptance in batches. A batch of wire must consist of spools with wire from one melt, patented for one thermal regime.

3.2. Each spool of wire is checked for appearance, surface condition and diameter.

3.3. To check the tensile strength, chemical composition, microstructure and decarburization, 5% of the spools are selected, but not less than three, from which one sample is taken from the outer end.

3.4. Checking the weight of the wire on the spool is carried out in doubtful cases.

3.5. The appearance and condition of the surface is checked

3

by inspection with the naked eye.

3.6. The wire diameter is measured with a micrometer with an accuracy of up to 0.01 mm in two mutually perpendicular directions of one section at any point along the length of the wire section on the spool.

3.7. Determination of tensile strength is carried out in accordance with GOST 10446-63.

3.8. The chemical composition is determined in accordance with GOST 11655-65 - 11662-65 and GOST 2331-63.

3.9. The microstructure of the wire is determined on longitudinal sections at a magnification of at least 500 x .

3.10. The depth of the decarburized layer is determined according to GOST 1763-68 (method M) in the delivery condition.

3.11. If unsatisfactory test results are obtained for any indicator, repeat tests are carried out on a double number of samples taken from the wire that failed the test. The results of the repeat tests are final.

4. PACKAGING, MARKING, TRANSPORTATION AND STORAGE

4.1. The wire on the spool must be wrapped in anti-corrosion (inhibited) paper grade UNI-22-80 according to GOST 16295-70 and polyethylene film or cotton tape and tied with soft wire.

4.2. Each spool of wire must be securely attached with a metal tag indicating:

a) the name or trademark of the manufacturer,

b) steel grades,

c) melt numbers,

d) wire diameter,

d) the number of pieces of wire on the spool,

e) production dates and quality control stamps.

4.3. Each batch of wire must be provided with a certificate,

4

certifying the compliance of the supplied wire with the requirements of these technical conditions, which must indicate:

a) the name or trademark of the manufacturer,

b) the number of these technical conditions,

c) steel grade and melt number,

d) wire diameter,

d) quantity (weight) of wire,

e) chemical composition and results of mechanical properties tests,

g) results of microstructure and decarburization analyses,

c) results of wire rod tests for non-metallic inclusions and macrostructure.

4.4. The weight of the shipped batch of wire must be no less than 0.5 tons and no more than 5 tons.

4.5. Wire transportation must be carried out by any type of transport under conditions that exclude moisture ingress. No more than 2 batches may be shipped simultaneously in one wagon, container or truck, provided that they are reliably separated.

4.6. The wire must be stored in a dry, indoor area in conditions that exclude exposure to moisture and aggressive environments.

5. PROCEDURE FOR PAYMENT FOR PRODUCTS

5.1. The price is set according to the appendix.

HEAD OF DEPARTMENT STANDARDIZATION OF VNIIMETIZ |

REGISTERED: "4" ff January ff 1977 I. BARYSHEVA |

Volkov

12-tv

4.08.76

5

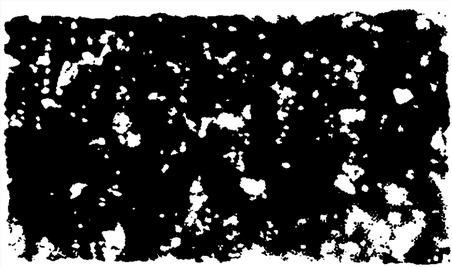

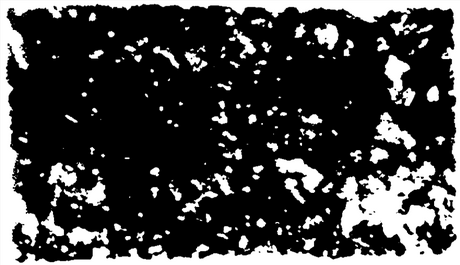

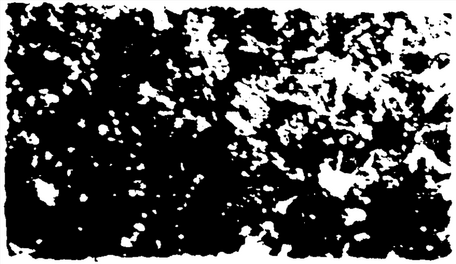

Appendix 1

PHOTO STANDARDS

OF ALLOWED MICROSTRUCTURES OF PATENTED

WIRES MADE OF BP-5 STEEL, diameter 1.4 mm

|

|

Sorbitol with the presence of rare

fuzzy grains of lamellar

perlite x500

Sorbitol with the presence of small

ferrite areas and eroded

grains of lamellar perlite.

x500

|

Sorbitol with grains lamellar perlite. x500 |

Appendix to TU 14-4-775-76

Wholesale price for high carbon wire used as a core in the manufacture of bimetallic wire

| Technical conditions | Steel grade | Diameter in mm | Wholesale price in rubles per ton |

| TU 14-4- -76 | BP5-Sh | 1.4 | 916 |

Note: General guidelines apply to wholesale prices

price list No. 01-05-1975, part 2.

Head of the Price Laboratory

VNIIMETIZ V.A. Serkin

"2" December 1976

Ministry of Ferrous Metallurgy

USSR

UDC Group B 72 I APPROVE Chief Engineer of VPO Soyuzmetiz USSR World Junior Championships V.I. ORINICHEV « 1 » ff December ff 1981 |

HIGH CARBON STEEL WIRE

MADE OF HIGH-PURE METAL

Technical conditions

TU 14-4-775-76

Change 1

Date of introduction: 01.03.1982

1. The validity period of the technical conditions has been extended until 01.03.87.

2. On the title page of the technical specifications, in the left part of field 2, enter the OKP code 12 2100.

3. Clause 2.1. Replace the reference to TU 14-4-4-71 with TU 14-1-2113-77.

4. Clause 2.3. To be stated as follows:

"Temporary tensile strength 1340-1470 N/mm² (137-147 kgf/mm²);

By agreement of the parties, delivery of wire with a tensile strength of 1380-1510 N/mm² (141-151 kgf/mm²) is permitted.

The variation in the temporary tensile strength of the wire on the spool

- 2 -

80 N/mm² (8 kgf/mm²) is allowed."

5. Clause 3.8 shall be amended as follows:

"The chemical composition is determined in accordance with GOST 22536.0-77 - 22536.5-77, GOST 22536.7-77 - 22536.9-77, GOST 22536.13-77."

6. Clause 4.1. Replace the reference to GOST 16295-70 with GOST 16295-77.

Agreed: Chief Engineer of Magnitogorsk hardware and metallurgical plant S.M. PETRIK "10" _____ 11 _____ 1981 Chief Engineer of Beloretsky metallurgical plant V.K. LIKHOV Agreed by letter No. 04-2980 from 30.09.81 |

Developed by: Chief Engineer of VNIImetiz K.G. ZALYALYUTDINOV "9" _____ 11 _____ 1981 |

Registered: "30" ___ December ___ 1981 Head of the Standardization Department and the quality of VNIImetiz |

I.V. BARYSHEVA |

Ministry of Ferrous Metallurgy of the USSR

| OKP 122100 | UDC Group B 72 I APPROVE Chief Engineer of the VPO "Soyuz- hardware" of the USSR Ministry of Ferrous Metallurgy __________ V.I. Orinichev " " 1985 |

HIGH CARBON STEEL WIRE

MADE OF HIGHLY PURE METAL

TECHNICAL SPECIFICATIONS

TU 14-4-775-76

Change #2

Introduction period:

AGREED Chief Engineer of Magnitogorsk hardware and metallurgical plant __________ V.V. Veremeenko «16» _____ 05 _____ 1985 Deputy Director of VNIImetiz on scientific work __________ V.I. Mokrinsky "15" _____ 05 _____ 1985 |

DEVELOPED BY Chief Engineer of Beloretsky metallurgical plant __________ V.S. Emchenko "30" _____ 05 _____ 1985 |

Clause 2.1. Table 1 shall be set out in a new version:

| Steel grade | Content of elements, % | |||||||

| C | Mn | Si | S | P | Cu | Ni | Cr | |

| no more | ||||||||

| 90-Sh (BP5-Sh) | 0.88-0.93 | 0.30- -0.60 |

0.20- -0.37 |

0,015 | 0,015 | 0.05 | 0.05 | 0.05 |

Amendment No. 2 to TU 14-4-775-76 Page 2

Clause 3.7. Replace the reference: GOST 10446-63 with GOST 10446-80.

Replace the link: GOST 16295-75 with GOST 16296-82.

The technical specifications shall be supplemented with Appendix 2 - Form 3.1A (Sheet 7).

Sheet 2. In the lower stamp, in the "sheets" column, indicate "7".

Acting Head of Standardization Department and the quality of VNIImetiz |

Registered: "3" July 1985 N.A. Galkina |

Appendix 2

to TU 14-4-775-76

Form 3.1A (mandatory)

| Name of the type of product according to NTD | Product type code according to VKG OKP | ||

| High-carbon steel wire made of ultra-pure metal | 12 2100 | ||

| Blocks according to OKP | Designation according to NTD | Codes according to OKP | |

| Steel grades | 90-Sh (BP5-Sh) | 3722 | |

| Profiles | technical conditions | 8198 | |

Technical requirements |

TU 14-4-775-76 | 7230 | |

Order form and delivery conditions |

reels (spools) | 36 | |

Calculation of codes checked:

Senior Research Fellow

V.A. Kudashev standardization laboratories

Head of the Standardization Department

and qualities of N.A. Galkin

| TU 14-4-775-76 | Sheet | |||||

| 7 | ||||||

| Change | Sheet | Doc. No. | Signature | Date |

Ministry of Ferrous Metallurgy of the USSR

| OKP 12 2100 | Group B 72 I APPROVE: Deputy Director of VNIImetiz on scientific work H.N. Belalov "2" _____03_____ 1989 |

HIGH CARBON STEEL WIRE

MADE OF HIGHLY PURE METAL

TECHNICAL SPECIFICATIONS

TU 14-4-775-76

Change #5

The holder of the original is Beloretsk Metallurgical Plant

Implementation date: 01.05.89

AGREED: Chief Engineer of Magnitogorsk hardware and metallurgy plant MChM USSR V.V. Veremeenko "17" _____03_____ 1989 Head of the State Acceptance Authority at Beloretsk Metallurgical Plant plant V.A. Igumnov "15" _____03_____ 1989 |

DEVELOPED BY: Chief Engineer of Beloretsky metallurgical plant V.S. Emchenko "15" _____03_____ 1989 |

1. Point 2.6. Add the following words to the first sentence:

"and on reels with a capacity of 500 kg, manufactured according to TU 14-4-314-73."

The examination has been carried out Head of the Standardization Department VNIImetiza N.A. Galkina March 17, 1989 |

EXPLANATORY NOTE

To the draft amendment No. 5 to the technical conditions

TU 14-4-775-76 "High-carbon steel wire

made of especially pure metal"

Amendment Project No. 5 was developed with the aim of increasing the productivity of heat-etching units when switching to winding wire onto 500 kg capacity spools.

Head of the Technical Department V.D. Miroshnichenko