Article on boron steel

UDC 621.039.531

POSSIBILITIES OF APPLICATION OF BORON STEELS

IN EXISTING AND PROSPECTIVE NUCLEAR REACTORS

© 2012 D. V. Kozlov 1 , V. D. Risovany 2

1 Ulyanovsk State University

2 JSC "SSC RF RIAR", Dimitrovgrad

Received by the editors on 20.11.2012

The article considers the issues of application of boron steels as absorbing materials for manufacturing of control and protection elements. The article considers steels of SB and SBYa grades, in which boron alloying up to the level of 2.0-2.2% (mass.) is carried out. Such a high boron content affects both the initial properties of steel and the evolution of properties and microstructure under irradiation. The article considers examples of operation of boron steels in various temperature and neutron-physical conditions, features of accumulation and redistribution of transmutation helium, issues of dimensional stability, changes in plasticity, strength, etc.

Key words: boron steels, absorbent materials, nuclear reactor control bodies.

Boron, like carbon, has a very strong effect on the properties of steels even in very small concentrations. The introduction of several thousandths of a percent of boron into some structural steels improves the resulting mechanical properties, and boron alloying can in some cases serve as a successful replacement for alloying with more expensive elements.

In addition, boron, or more precisely its isotope 10 B, is one of the most effective neutron absorbers and this property is successfully used in nuclear power engineering. The most common use of boron is in the form of tablets or boron carbide powder, usually poured into a cylindrical shell and forming the core of the absorber element (i.e., the element that absorbs neutrons). Depending on the depth of immersion of the absorbers in the active zone, an increase or decrease in the power of the active zone occurs, or even its emergency shutdown occurs in the event of abnormal situations. In some cases, sufficient neutron-physical efficiency can be ensured by using steel with a boron content of about 1-2% as an absorbing material (a higher boron content makes steel brittle). In this case, boron steel can be used as a core, with a casing made of some other material, or without a casing, simultaneously performing the role of a structural and functional (neutron-absorbing) material.

PROPERTIES OF BORON STEELS USED IN NUCLEAR POWER ENGINEERING

In Russia, boron steels of the SB and SBYA grades have found practical application; their chemical composition is given in Table 1.

Melting of boron steels is carried out in induction furnaces. In this case, boron losses do not exceed 5% of the initial content. Processing by forging at a temperature of 1010-1150 °C is possible. At a temperature below 1010 °C, the steel becomes brittle, and at a temperature above 1150 °C, it becomes red-brittle [1, 2].

The structure of boron steel consists of a solution of chromium in the gamma phase of iron and a boride phase (CrB, FeB), which has a lath shape on metallographic sections [3, 4]. When alloyed with tungsten and molybdenum, the heat resistance of the steel increases and the boride phase is refined, which allows the use of SB-2 steel at a higher operating temperature [4].

The thermophysical properties of boron steels are close to those of stainless steels. Boron steels have a fairly high corrosion resistance when working in a water coolant. The rather low ductility of boron steels causes technological difficulties in forging, rolling and pressing products from them. Welding of boron stainless steels to obtain seams equivalent in strength to the welded material is carried out with a double V-shaped preparation of the welded edges and surfacing of the seam with an argon-arc torch with a special electrode. grinding has a rack shape [3, 4]. When alloying with tungsten and molybdenum, the heat resistance of the steel increases and the boride phase is crushed, which allows the use of SB-2 steel at a higher operating temperature [4].

The thermal properties of boron steels are close to those of stainless steels. Boron steels have a fairly high corrosion resistance when working in a water coolant. The rather low plasticity of boron steels causes technological difficulties in forging, rolling and pressing products from them. Welding of boron stainless steels to obtain seams equivalent in strength to the welded material is performed with a double V-shaped preparation of the welded edges and surfacing of the seam with an argon-arc torch with a special electrode.

Table 1. Mass content of alloying elements in boron steels

Brand Mass content, % Fe B Cr Ni Co Al C Mo W SB-2 Warp 2.0-2.2 17-20 32-36 - - - 7-9 3-4 SBYa-2 1.6-2.0 19-22 15-18 0.02 0.4 0.05 - -

Mechanical processing of cast blanks made of boron steels with a boron content of up to 2% is performed using cutters made of ordinary high-speed steel.

The radiation resistance of boron steels, according to the data given in work [1], is characterized by:

- a decrease in viscosity from 60 to 90% at a neutron fluence of F = 3.10 20 cm -2 ;

- an increase in the linear dimensions of samples by 1-2% at F= 1.10 20 cm -2 ;

- increasing the tensile strength by 50-100

% at F = 3.10 20 cm -2 ;

- an increase in the yield strength by more than 200% at F = 3.10 20 cm -2 .

The data presented show that it is advisable to make the elements of the control organs from boron steels cast with subsequent mechanical processing. The use of these parts as load-bearing is undesirable, and their installation on load-bearing elements should take into account the possibility of swelling and changes in geometry during operation in the reactor.

APPLICATION OF BORON STEEL IN OPERATING REACTORS

In nuclear engineering, boron steel inserts are used, which have a hexagonal or ring-shaped cross-section. Hexagonal inserts are used in WWER-440 reactors. Inserts in the form of ring bushings have found application, in particular, in the control bodies of the RBMK-1000, VK-50, WWER-2 reactors of the Rheinsberg NPP.

The SBYa-2 boron steel products were examined after operation as part of the additional absorber (AA) rods at the Leningrad NPP (RBMK-1000) for 826 effective days at a water temperature of 270 °C, a pressure of 7.4 MPa to a maximum neutron fluence of 2.1 x 10 21 cm -2 . Cracks were observed on some bushings; their diameter increased by 4.9%. The bushings that remained intact had an increase in diameter of up to 1.1%. Cracks and failures of the bushings were noted after irradiation for 608 effective days. The proportion of bushings with cracks was more than 5% of the total number examined. The main causes of bushing cracking are a decrease in the plasticity of the metal matrix under irradiation and the accumulation of helium formed by the n-reaction on the 10 B isotope. In addition, during the manufacturing of bushings, the formation of cavities, inclusions, and other inhomogeneities is inevitable, which, when irradiated, become stress concentrators and cause destruction. Stresses in bushings arise both from external influences (coolant pressure, movement of products) and from uneven burnout of 10 B isotopes across the cross-section of samples.

The works [5,6] present data on the study of hexagonal bushings made of boron steel SBYa-2, which were operated in the WWER-2 reactor of the Rheinsberg NPP for seven calendar years up to the maximum thermal neutron fluence of 3.14.10 21 cm -2 . Cracks, changes in shape and abrasions were absent. Volumetric swelling of the material reached 1.7%, which caused an increase in the spanner size of about 0.16 mm. After annealing at a temperature of 800 єC for 1-3 hours, the volumetric swelling of the material was 4.3-4.7%.

Samples measuring 6x6x50 mm were cut from the hexagon face. In some cases, explosive destruction of the samples occurred due to the brittleness of the material and the presence of high stresses in it. The strength characteristics of the steel increased almost twofold. When testing the cut samples for bending, the ultimate strength increased from 630-860 MPa for the unirradiated material to 1100-1500 MPa after reactor irradiation. The plastic deflection decreased accordingly from 0.153 - 0.293 mm to zero. The microhardness of the matrix increased by 60% (from 1560 to 2300-2500 MPa).

After irradiation, cavities filled with helium were found in the microstructure of the steel. The cavities were predominantly located around the borides. The distribution of cavities across the cross-section of the samples was uneven. The burnout of the 10 B isotope was measured across the 6 mm thick bushing wall (Fig. 1). The burnout was 45-60% on the outer side of the bushing, 37-46% on the inner side, and 24-33% in the central region. The higher burnout of the 10 B isotope on the inner surface of the bushings compared to the central layers of the material is due to the "trap" effect resulting from the slowing down of neutrons in the water filling the inner cavity of the bushings.

Fig. 1. Dependence of the 10 B isotope burnup on the wall thickness of the SBYa-2 steel bushing after irradiation in the WWER-2 reactor of the Rheinsberg NPP for 7 years to a neutron fluence of 3.14 × 10 21 cm -2

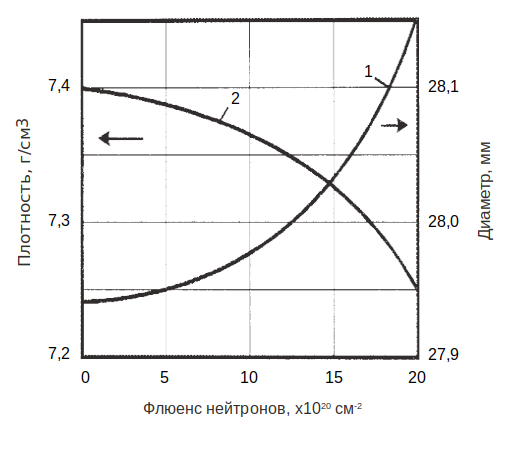

Fig. 2. Dependence of the change in diameter (1) and density (2) of SB-2 steel bushings on the neutron fluence (E>0.8 MeV) at an irradiation temperature of 400-820 o C

The SB-2M steel bushings were used in the control units of the Bilibino NPP for 1523 effective days at a temperature of 500-600 o C up to a maximum neutron fluence of 2.4 x 10 21 cm -2 . The maximum increase in the bushing diameter (39 x 3 mm) was 1.9%. The increase in the diameter of bushings with cracks exceeded 2.0%. As a result of systematic measurements, the dependence of the increase in linear dimensions (diameter) on the neutron fluence was determined:

where F is the neutron fluence, cm -2 .

The efficiency of the AR rod, which was constantly in the reactor core during operation for 921 effective days, decreased by 20% compared to the initial value.

The study involved SB-2 boron steel bushings irradiated in the AST-1 reactor control units. The service life of the products was 469 effective days at a reactor power of 5 MW. Irradiation was performed in air at a bushing temperature of 400-820 o C to a maximum fluence of fast (E > 0.8 MeV) thermal (E < 0.5 eV) neutrons of 2.16 x 10 21 and 0.84 x 10 21 cm -2 , respectively. After reactor tests, the bushings had a shiny surface; no visible corrosion or mechanical damage was detected.

As a result of irradiation with increasing neutron fluence, the diameter of the bushings increased with a simultaneous decrease in the density of the material (Fig. 2). The maximum decrease in density and increase in diameter of SB-2 steel at a neutron fluence of 2.10 21 cm -2 (E> 0.8 MeV) was 2.02 and 0.75%, respectively.

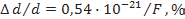

As a result of metallographic studies, no noticeable differences in the structure of boron steel after reactor tests were revealed (Fig. 3). With an increase in neutron fluence, the material became stronger. At a neutron fluence of 10 21 cm -2 (E > 0.8 MeV), the microhardness of H was 3200 MPa, and H at 2.10 21 cm -2 (E> 0.8 MeV) = 4000 MPa.

Fig. 3. Structure of boron steel SB-2

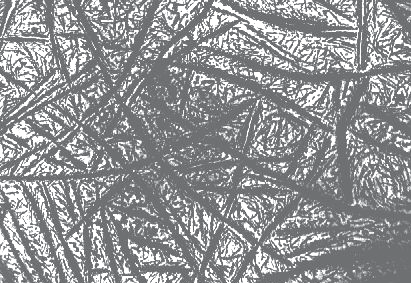

Fig. 4. Relative change in mechanical characteristics of boron steels depending on the content

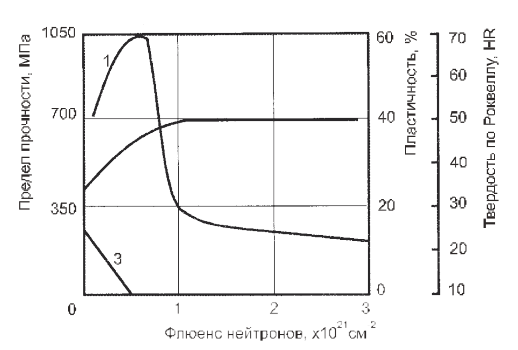

Fig. 5. Change in mechanical characteristics of boron steel with a boron mass content of 1% from neutron fluence [7]: strength limit (1); hardness (2); elongation (3)

Similar results are given in [3, 4]. Boron steel with a wide range of boron content was studied: 0.3-3.0%. In austenitic boron stainless steels with a 10 B content from 0.5 to 1.0%, irradiated to a neutron fluence of 1 10 20 cm -2 , the dimensions increased by 1-2%, and with 35% burnout of the 10 B isotope, the dimensions changed by 2.3 and 4.2

% respectively. As a result of irradiation of a number of

boron steels at temperatures of 530-660 and 750-870 o C, their structure, volume and mechanical properties changed.

The results of the change in the mechanical properties of boron steels depending on their boron content are presented (Fig. 4.) [7]. With an increase in the boron content from 0.25 to 1%, the hardness HR increased by 2.8 times, the ultimate strength in by 1.4

times, plasticity decreased by more than 2, and resistance to impact loads by 4 times.

It is shown that with an increase in neutron fluence at the early stages of irradiation, a sharp increase in the ultimate strength is observed. For an alloy with a boron content of 1%, the strength increases by 50% at a neutron fluence of 5 1020 cm-2 (Fig. 5). In this case, the plasticity decreases to almost zero. Subsequent irradiation is accompanied by a decrease in the strength of the material, and at a neutron fluence of 1 1021 cm-2 it becomes two times less than the initial values. During irradiation, the hardness of the material also changed, which at a neutron fluence of 1 1021 cm-2 increased almost 2 times. Further irradiation was not accompanied by an increase in hardness [7].

As can be seen from the above data, this accumulation is quite significant and causes both strengthening and radiation swelling of products. Helium bubbles at sufficiently high fluences are detected at the boundaries of borides, and irradiation at medium and high temperatures (400 0 C and above) lead to their formation far from the particles of boron-containing phases. Unevenness of 10 B burnout over the section of products leads to uneven swelling and the occurrence of a significant gradient of mechanical stresses. Together with a decrease in plasticity caused by radiation hardening, this facilitates the occurrence of cracks. At the same time, the detected effects significantly depend on the irradiation parameters, such as irradiation temperature, neutron spectrum, accumulated fluence, and at the same time can be leveled by changing the design of the absorbing elements. For example, mechanical stresses that arise when a thick-walled bushing swells can be reduced by replacing it with several thin-walled bushings nested one inside the other, etc.

At the same time, at moderate fluences, it is possible to use boron-containing steels at fairly high temperatures of the order of 500-700 0 C. This allows us to speak of them as candidate materials primarily for reactor units with pressurized water, which are currently being developed. Of particular interest may be the use of such absorbing materials in reactors of the KLT-40 type and similar ones, which are being developed for floating NPPs, where the comparatively low energy intensity of the active zone and low operating temperature allow us to assume a long service life.

DISCUSSION

The high boron content required to ensure neutronic efficiency is the cause of the main neutron-induced phenomenon of accumulation and redistribution of transmutational helium.

CONCLUSION

- The effect of neutron irradiation on the microstructure and mechanical properties of boron-containing steels is manifested in "traditional" strengthening, a decrease in plasticity and embrittlement associated with the formation of radiation defects, as well as in the accumulation and diffusion redistribution of transmutation helium formed during the 10 B (n, alpha) reaction.

- Accumulating helium, in addition to influencing mechanical properties, is the cause of radiation swelling, leading to changes in the shape of parts, and, as a consequence, significant stress gradients in thick-walled structures. To some extent, the growth of helium bubbles and the swelling associated with it decreases with a decrease in temperature below 350-300 ° C.

- The use of such absorbing materials in reactors of the KLT-40 type and similar ones, developed for floating nuclear power plants, where the relatively low energy intensity of the active zone and low operating temperature allow us to assume a long service life, may be promising.

The work was carried out with the support of the Ministry of Education and Science within the framework of the Federal Targeted Program "Scientific and Scientific-Pedagogical Personnel of Innovative Russia" for 2009-2013 and the state assignment for 2012-2014.

LIST OF REFERENCES

- Emelyanov I.Ya., Efanov A.I., Konstantinov L.V. Scientific and technical foundations of nuclear reactor control. Moscow, Energoizdat, 1981, 360 p.

- Prus LB, Byron ES, Thompson JF Nucl. Sci. Eng., 1958. V.4.R.415.

- Emelyanov I.Ya., Grebennikov R.V., Sergeev B.S. et al. Effect of tungsten and molybdenum on radiation resistance of boron-chromium-iron-nickel alloy. Proceedings of the CMEA Conference "Nuclear Power Engineering, Fuel Cycles, Radiation Materials Science" Moscow, CMEA Publishing House, 1971, pp. 495-505

- Kotelnikov Yu.G., Ponomarenko V.B., Chernyshov V.M. et al. Current state of problems of absorbing materials for nuclear reactors of various purposes. Proceedings of the third interdisciplinary conference on reactor materials science. Dimitrovgrad, 1994. Vol.1. Pp.12-25.

- Kuznetsov S.A., Ponomarenko V.B., Melamed V.E. et al. Radiation resistance of absorbing materials for control bodies of the control and protection system of nuclear reactors of NPPs // Collection of reports of the International Conference on Radiation Materials Science. Kharkov: KhPTI, 1990. Vol.3, pp.189-198.

- Murgatroyd RA, Kelly BT Technology and assessment of neutron absorbing materials. J. Atomicenergyreview. 1977. v.15. No. 1. P.3-74.

- Report on the main research works carried out in 2000. Dimitrovgrad: State Scientific Center of the Russian Federation Research Institute of Atomic Reactors, 2001. P.43-44.

- Khudyakov A.A., Ostrovsky Z.E., Risovany V.D., et al. State of the SBYa alloy after 31 years of operation in the VK-50 reactor // Atomic Energy. 2002. Vol. 92. Issue 2. Pp. 114-118.