GOST 6235-2020

INTERSTATE COUNCIL FOR STANDARDIZATION, METROLOGY AND CERTIFICATION

(MGS)

INTERSTATE COUNCIL FOR STANDARDIZATION, METROLOGY AND CERTIFICATION

(ISC)

INTERSTATE |

GOST 2020 |

NICKEL SHEETS AND STRIPS

Technical conditions

Official edition

GOST 6235-2020

Preface

The objectives, basic principles and general rules for carrying out work on interstate standardization are established by GOST 1.0 "Interstate standardization system. Basic provisions" and GOST 1.2 "Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Rules for development, adoption, updating and cancellation"

Information about the standard

1 DEVELOPED BY the Technical Committee for Standardization TC 106 "Non-ferrous Metals Rolling", Joint-Stock Company "Research, Design and Engineering Institute of Alloys and Processing of Non-Ferrous Metals" (JSC "Institute Non-Ferrous Metals Rolling")

2 SUBMITTED by the Federal Agency for Technical Regulation and Metrology

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (minutes of June 30, 2020 No. 131-P)

The following voted for adoption:

| Short name of the country according to MK (ISO 3166) 004-97 | Country code according to MK (ISO 3166) 004-97 | Abbreviated name of the national standardization body |

Armenia Belarus Kyrgyzstan Tajikistan |

AM BY KG TJ |

Ministry of Economy of the Republic of Armenia State Standard of the Republic of Belarus Kyrgyzstandart Tajikstandard |

5 INSTEAD OF GOST 6235-91

Information on the entry into force (termination of force) of this standard and amendments to it in the territory of the above-mentioned states is published in the indexes of national standards published in these states, as well as on the Internet on the websites of the relevant national standardization bodies.

In case of revision, amendment or cancellation of this standard, the relevant information will be published on the official website of the Interstate Council for Standardization, Metrology and Certification in the catalog "Interstate Standards"

GOST 6235-2020

Content

1 Scope 1

2 Normative references 1

3 Terms and definitions 3

4 Assortment 3

5 Technical requirements 6

6 Acceptance rules 7

7 Methods of control and testing 9

8 Packaging, labeling, transportation and storage 10

Appendix A (informative) Thickness and theoretical weight of 1 m² of hot-rolled sheets

and hot-rolled and cold-rolled strips 12

GOST 6235-2020

INTERSTATE STANDARD

NICKEL SHEETS AND STRIPS

Technical conditions

Strips and ribbons of nickel. Specifications

Date of introduction - 2021-04-01

1 Scope of application

This standard applies to hot-rolled nickel sheets and hot-rolled and cold-rolled strips (sheets and strips) used in various industries.

2 Normative references

This standard uses normative references to the following interstate standards:

GOST 166 (ISO 3599-76) Calipers. Specifications

GOST 427 Measuring metal rulers. Technical conditions

GOST 492 Nickel, nickel and copper-nickel alloys processed by pressure. Brands

GOST 1497 (ISO 6892-84) Metals. Tensile testing methods

GOST 2991 Non-collapsible wooden boxes for loads weighing up to 500 kg. General specifications

GOST 3282 General-purpose low-carbon steel wire. Specifications

GOST 3560 Steel packaging tape. Technical conditions

GOST 6012 Nickel. Methods of chemical-atomic emission spectral analysis

GOST 6507 Micrometers. Specifications

GOST 6689.1 Nickel, nickel and copper-nickel alloys. Methods for determination of copper

GOST 6689.2 Nickel, nickel and copper-nickel alloys. Methods for determination of nickel

GOST 6689.3 Nickel, nickel and copper-nickel alloys. Methods for determining the amount of nickel and cobalt

GOST 6689.4 Nickel, nickel and copper-nickel alloys. Methods for determination of zinc

GOST 6689.5 Nickel, nickel and copper-nickel alloys. Methods for determination of iron

GOST 6689.6 Nickel, nickel and copper-nickel alloys. Methods for determination of manganese

GOST 6689.7 Nickel, nickel and copper-nickel alloys. Methods for determination of silicon

GOST 6689.8 Nickel, nickel and copper-nickel alloys. Methods for determination of aluminum

GOST 6689.9 Nickel, nickel and copper-nickel alloys. Methods for determination of cobalt

GOST 6689.10 Nickel, nickel and copper-nickel alloys. Methods for determination of carbon

GOST 6689.11 Nickel, nickel and copper-nickel alloys. Methods for determination of tungsten

GOST 6689.12 Nickel, nickel and copper-nickel alloys. Methods for determination of magnesium

GOST 6689.13 Nickel, nickel and copper-nickel alloys. Methods for determination of arsenic

GOST 6689.14 Nickel, nickel and copper-nickel alloys. Methods for determination of chromium

GOST 6689.15 Nickel, nickel and copper-nickel alloys. Methods for determination of antimony

GOST 6689.16 Nickel, nickel and copper-nickel alloys. Methods for determination of zinc, cadmium, lead, bismuth and tin

Official edition

1

GOST 6235-2020

GOST 6689.17 Nickel, nickel and copper-nickel alloys. Methods for determination of bismuth

GOST 6689.18 Nickel, nickel and copper-nickel alloys. Methods for determination of sulfur

GOST 6689.19 Nickel, nickel and copper-nickel alloys. Methods for determination of phosphorus

GOST 6689.20 Nickel, nickel and copper-nickel alloys. Methods for determination of lead

GOST 6689.21 Nickel, nickel and copper-nickel alloys. Methods for determination of titanium

GOST 6689.22 Nickel, nickel and copper-nickel alloys. Methods for determination of tin

GOST 7376 Corrugated cardboard. General specifications*

GOST 7502 Measuring metal tapes. Technical conditions

GOST 7933 Cardboard for consumer packaging. General specifications

GOST 8273 Wrapping paper. Technical conditions

GOST 8828 Base paper and two-layer waterproof packaging paper. Technical conditions

GOST 10198 Wooden boxes for cargo weighing over 200 to 20,000 kg. General specifications

GOST 10510 (ISO 8490-86) Metals. Erichsen extrusion test method for sheets and strips

GOST 11358 Thickness gauges and wall thickness gauges with a division value of 0.01 and 0.1 mm. Technical conditions

GOST 13047.1 Nickel. Cobalt. General requirements for analysis methods

GOST 13047.2 Nickel. Cobalt. Methods for determination of nickel in nickel

GOST 13047.3 Nickel. Cobalt. Methods for determination of cobalt in cobalt

GOST 13047.4 Nickel. Cobalt. Methods for determination of cobalt in nickel

GOST 13047.6 Nickel. Cobalt. Methods for determination of carbon

GOST 13047.7 Nickel. Cobalt. Methods for determination of sulfur

GOST 13047.14 Nickel. Cobalt. Methods for determining bismuth

GOST 13047.17 Nickel. Cobalt. Methods for determination of iron

GOST 13047.18 Nickel. Cobalt. Methods for determination of arsenic

GOST 14019 (ISO 7438:1985) Metallic materials. Bending test method

GOST 14192 Marking of cargo

GOST 15102 General-purpose closed metal container with a nominal gross weight of 5.0 t. Technical conditions

GOST 15846 Products shipped to the regions of the Far North and equivalent localities. Packaging, labeling, transportation and storage

GOST 18242 Statistical acceptance testing by an alternative attribute. Control plans**

GOST 18321 Statistical quality control. Methods of random sampling of individual products

GOST 18477 Universal containers. Types, main parameters and dimensions

GOST 20435 General-purpose closed metal container with a nominal gross weight of 3.0 t. Technical conditions

GOST 21140 Container. Dimension system

GOST 21650 Means of fastening unit-piece cargo in transport packages. General requirements

GOST 22225 General-purpose containers with a gross weight of 0.625 and 1.25 tons. Technical conditions

GOST 24047 Semi-finished products from non-ferrous metals and their alloys. Sampling for tensile testing

GOST 24231 Non-ferrous metals and alloys. General requirements for sampling and preparation of samples for chemical analysis

GOST 24597 Packages of unit-packaged cargo. Basic parameters and dimensions

GOST 26653 Preparation of general cargo for transportation. General requirements

GOST 26663 Transport packages. Formation using packaging means. General technical requirements

GOST 26838 Wooden boxes and battens. Mechanical strength standards

GOST 26877 Metal products. Methods for measuring shape deviations

GOST 33757 Flat wooden pallets. Technical conditions

* GOST R 52901-2007 "Corrugated cardboard for product packaging. Technical conditions" is in effect.

** GOST R ISO 2859-1-2007 "Statistical methods. Sampling procedures for inspection by an alternative attribute. Part 1. Sampling plans for inspection of successive lots based on an acceptable quality level" is in effect.

2

GOST 6235-2020

Note - When using this standard, it is advisable to check the validity of referenced standards and classifiers on the official website of the Interstate Council for Standardization, Metrology and Certification or in the indexes of national standards published in the countries specified in the preface, or on the official websites of the relevant national standardization bodies. If an undated reference to a document is given, the document in effect at the current moment should be used, taking into account all changes made to it. If a referenced document to which a dated reference is given has been replaced, the specified version of this document should be used. If, after the adoption of this standard, a change is made to a referenced document to which a dated reference is given that affects a provision to which a reference is given, this provision shall be applied without taking into account this change. If a referenced document is cancelled without replacement, the provision in which a reference to it is given shall be applied in the part that does not affect this reference.

3 Terms and definitions

The following terms and definitions are used in this standard:

3.1 sheet: A flat semi-finished product of rectangular cross-section, over 0.1 mm thick, manufactured

rolling.

3.2 strip: A flat semi-finished product of rectangular cross-section with a length to width ratio of not

less than 5, with a thickness of over 0.1 mm, produced by rolling or cutting sheets and strips.

3.3 darkening: A defect in the form of a continuous dark surface of the product.

3.4 annealing colors: A surface defect that is an iridescent oxide film,

present on the plain surface of the product.

3.5 traces of unburned grease: Surface defect in the form of spots, streaks, drips and stains.

3.6 burr: A surface defect that is a sharp, ridge-shaped protrusion or

a strip of metal twisted into a spiral at the point where an ingot or semi-finished product is cut.

3.7 scale rolling: A surface defect in the form of inclusions of scale residues pressed into the

metal surface during deformation.

3.8 delamination: A surface defect in the form of a discontinuity in the metal oriented

along the direction of deformation.

3.9 crack: A defect in the form of a local rupture of metal of varying size, having any

direction.

3.10 camber: A deviation in shape in which the edges of a sheet or strip in the horizontal

the planes have the shape of an arc.

3.11 wrinkled, wavy edge: A shape defect in the form of local wrinkled edge of a flat semi-finished product.

3.12 torn edge: A surface defect of a flat semi-finished product in the form of a rupture of the metal along

edges.

3.13 cutting obliquity: Deviation from perpendicularity at which the cutting plane forms a

longitudinal planes of metal products at an angle different from 90°.

4 Assortment

4.1 The thickness and width of hot-rolled sheets and maximum thickness deviations must correspond to the values specified in Table 1.

Table 1 In millimeters

| Sheet thickness | Maximum deviations in thickness at sheet width | ||

| 500 | 600, 700 | 800 | |

| 5.0 | 0 -0.40 |

- | - |

| 6.0 | 0 -0.45 | ||

7.0 8.0 |

0 -0.50 | ||

3

GOST 6235-2020

End of table 1 In millimeters

| Sheet thickness | Maximum deviations in thickness at sheet width | ||

| 500 | 600, 700 | 800 | |

| 9.0 | 0 -0.50 |

0 -0.60 |

- |

| 10.0 | 0 -1.0 | ||

11.0 12.0 13.0 14.0 |

0 -0.80 |

0 -0.90 | |

15.0 16.0 17.0 |

0 -0.90 |

0 -1.0 |

0 -1,2 |

18.0 19.0 20.0 |

0 -1,2 |

0 -1.3 |

0 -1.5 |

| Note: At the customer's request, hot-rolled sheets are manufactured with more stringent maximum thickness tolerances. | |||

4.2 The maximum deviations in sheet width must correspond to the values specified in Table 2.

Table 2 In millimeters

| Sheet width | Maximum deviations in width with sheet thickness | |

| From 5.0 to 10.0 | From 11.0 to 20.0 | |

| 500, 600, 700, 800 | 0 -15 |

0 -20 |

4.3 The length of the sheets should be 500-2000 mm.

Sheets are produced in measured, multiples of 100 mm and non-measured lengths.

Maximum deviations in the length of sheets of measured and multiple measured lengths must not exceed minus 20 mm.

4.4 The thickness of hot-rolled strips and the maximum deviations for it must correspond to the values given in Table 3.

Table 3 In millimeters

| Strip thickness | Maximum deviations in strip thickness |

5.0-6.0 7.0-8.0 9.0-10.0 11.0 12.0 13.0-14.0 15.0-17.0 18.0-20.0 |

from 0 to -0.35 from 0 to -0.40 from 0 to -0.50 from 0 to -0.60 from 0 to -0.70 from 0 to -0.80 from 0 to -0.90 from 0 to -1.2 |

| Note: At the customer's request, hot-rolled strips are manufactured with stricter maximum thickness tolerances. | |

4

GOST 6235-2020

4.5 The width of hot-rolled strips and the maximum deviations for it must correspond to the values specified in Table 4.

Table 4 In millimeters

| Bandwidth | Maximum deviations in width with strip thickness | ||

| 5.0 | From 6.0 to 10.0 | From 11.0 to 20.0 | |

| 100, 150, 300 | 0 -4.0 |

0 -10.0 |

- |

| 100, 150 | - | - | 0 -15.0 |

| 300 | - | - | 0 -20,0 |

| Note: At the customer's request, hot-rolled strips are manufactured with more stringent maximum width tolerances. | |||

4.6 The length of hot rolled strips should be 400-2000 mm.

Hot rolled strips are produced in measured, multiple measured and non-measured lengths.

Maximum deviations in the length of hot-rolled strips must not exceed minus 15 mm.

4.7 The thickness of cold-rolled strips and the maximum deviations for it must correspond to the values specified in Table 5.

Table 5 In millimeters

| Strip thickness | Maximum deviations in strip thickness |

| 1.0 | 0 -0.08 |

| 1,2 | 0 -0.09 |

| 1.5 | 0 -0.10 |

| 1.8-2.0 | 0 -0.11 |

| 2.5-3.0 | 0 -0.12 |

| 3.5 | 0 -0.16 |

| 4.0 | 0 -0.18 |

| 4.5-5.0 | 0 -0.20 |

| 5.5-8.0 | 0 -0.25 |

| 9.0-10.0 | 0 -0.30 |

4.8 The width of cold-rolled strips and the maximum deviations for it must correspond to the values specified in Table 6.

Table 6 In millimeters

| Bandwidth | Maximum deviations in width with strip thickness | |||

| from 1.0 to 1.5 | from 1.5 to 3.0 | from 3.5 to 5.5 | from 6.0 to 10.0 | |

40,42,45,48,50,52,55, 60,63,65,70,75,80,85,90,95,100,105, 110,120,125,130,140,150,160,170 |

0 -1 |

0 -2 |

- | - |

5

GOST 6235-2020

End of table 6 In millimeters

| Bandwidth | Maximum deviations in width with strip thickness | |||

| from 1.0 to 1.5 | from 1.5 to 3.0 | from 3.5 to 5.5 | from 6.0 to 10.0 | |

175,180,190,200,210,220,240,250,260, 280,300 |

0 -2 |

0 -3 |

0 -4 |

0 -10 |

| 400 | 0 -3 |

0 -3 |

- | - |

4.9 The length of cold-rolled strips should be 400-2000 mm.

Cold rolled strips are produced in measured, multiple measured and non-measured lengths.

Maximum deviations in the length of the strips must not exceed minus 10 mm.

Note - The theoretical weight of 1 m² of sheets and strips is given in Appendix A.

4.10 By agreement between the consumer and the manufacturer, sheets and strips may be manufactured in intermediate sizes in thickness and width with maximum deviations for the next larger size given in Tables 1-6.

4.11 By agreement between the consumer and the manufacturer, sheets and strips may be manufactured with maximum deviations in thickness and width that differ from those given in Tables 1-6.

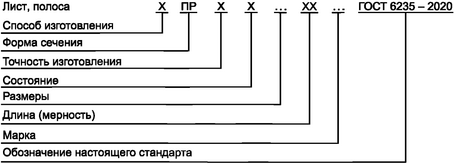

4.12 Conventional designations of sheets and strips should be indicated according to the diagram:

The following abbreviations are used:

manufacturing method: cold rolled - D,

hot rolled - G;

cross-section shape: rectangular - PR;

condition: soft - M,

solid - T;

length (dimension): multiple of dimension - KD,

non-dimensional - ND.

An "X" is placed in place of missing data.

Examples of conventional designations:

Hot-rolled sheet, 5.0 mm thick, 500 mm wide, 1000 mm long, made of NP2 grade nickel:

Sheet GPRHH 5.0×500×1000 NP2 GOST 6235-2020

Hot-rolled strip, 9.0 mm thick, 150 mm wide, 1500 mm long, made of NP3 grade nickel:

Strip GPRXX 9.0×150×1500 NP3 GOST 6235-2020

Cold-rolled strip 8.0 mm thick, 100 mm wide, 1000 mm long, made of NP2 grade nickel:

Strip DPRXX 8.0×100×1000 NP2 GOST 6235-2020

5 Technical requirements

5.1 Sheets and strips are manufactured in accordance with the requirements of this standard from nickel grades NP1, NP2, NP3 and NP4 with a chemical composition according to GOST 492.

6

GOST 6235-2020

5.2 Depending on the state of the material, cold-rolled strips are produced soft and hard.

5.3 The surface of sheets and strips must be free from contamination that impedes visual inspection.

5.4 No defects are allowed on the surface that would cause sheets and strips to exceed the maximum thickness deviations during control cleaning.

In addition, on the surface of hot-rolled sheets and strips, minor rolling of scale is allowed, which does not lead the sheets and strips beyond the maximum thickness deviations during control cleaning.

Local darkening, tempering colours and traces of unburnt grease are permitted on the surface of cold-rolled strips.

Requirements for surface quality are established based on samples approved in accordance with the established procedure.

5.5 By agreement between the consumer and the manufacturer, sheets and strips may be manufactured with surface quality requirements that differ from those specified in 5.4.

5.6 Sheets and strips must be cut evenly.

5.7 The cutting obliquity must not exceed the maximum deviations in width and length of sheets and strips.

5.8 At the request of the consumer, sheets and strips must not have wavy, wrinkled or torn edges, as well as burrs on the edge.

5.9 Hot rolled sheets and strips are manufactured with a thickness of over 20 mm without edge trimming, while maximum thickness deviations are set by agreement between the consumer and the manufacturer.

5.10 By agreement between the consumer and the manufacturer, sheets and strips may be manufactured with edge quality requirements that differ from those specified in 5.7 and 5.8.

5.11 Sheets and strips must not have any delamination.

5.12 At the customer's request, soft strips must withstand a cold bending test at an angle of 180° around a mandrel with a radius of curvature equal to the thickness of the strip, without the formation of traces of tears or cracks.

5.13 By agreement between the consumer and the manufacturer, the requirements for bending tests of soft strips may differ from those given in 5.12.

5.14 At the customer's request, the crescent shape of cold-rolled strips must not exceed 3 mm per 1 m of length.

5.15 By agreement between the consumer and the manufacturer, sheets and strips may be manufactured with requirements for crescent shape that differ from those specified in 5.14.

5.16 At the customer's request, the mechanical properties of sheets and strips must correspond to those specified in Table 7.

Table 7

| Material condition | Tensile strength, MPa (kgf/mm²), not less than | Relative elongation, %, not less than | Extrusion depth (according to Eriksen with punch radius of 10 mm), mm, not less than |

Hot rolled Soft Solid |

370 (38) 370 (38) 540 (55) |

15 35 2 |

- 8.5 - |

5.17 By agreement between the consumer and the manufacturer, sheets and strips may be manufactured with mechanical properties that differ from those given in Table 7.

The extrusion depth values for the spherical dimple drawing test may differ from those given in Table 7.

6 Acceptance Rules

6.1 Sheets and strips are accepted in batches. A batch must consist of sheets and strips of the same grade of nickel, the same size, the same material condition and be accompanied by one quality document containing:

- trademark or name of the manufacturer and trademark;

- name of the country of manufacture;

- legal address of the manufacturer and/or seller;

7

GOST 6235-2020

- conventional designation;

- batch number;

- test results;

- gross and net weight of the batch;

- number of cargo spaces.

The batch weight must not exceed 2500 kg.

It is permissible to issue one quality document for several batches of sheets or strips of nickel of the same grade, the same size, the same condition, shipped to the same consumer, indicating the batch numbers.

6.2 To control the dimensions and surface quality of sheets and strips, a single-stage normal sampling plan is used for alternative control in accordance with GOST 18242 with an acceptance level of defectiveness of 4%.

The selection of sheets and strips from a batch into a sample is carried out "blindly" (using the method of greatest objectivity) in accordance with GOST 18321.

The number of sheets and strips selected is determined in accordance with Table 8.

Table 8

| Number of sheets and strips in a batch, pcs. | Number of controlled sheets and strips, pcs. |

4-25 26-90 91-150 151-280 281-500 501-1200 1201-3200 |

3 13 20 32 50 80 125 |

| Note: If the batch size does not exceed three sheets or strips, each sheet or strip is tested. | |

The number of sheets and strips in a batch and the number of controlled areas on one sheet or strip are determined according to formulas (1) and (2) given in 7.2.

The number of controlled points on each selected sheet or strip is determined depending on the total number of sections 100 mm long around the perimeter of the sheet or strip in accordance with Table 9.

If the perimeter is not a multiple of 100 mm, the final section with a length of less than 100 mm is taken as one section.

Table 9

| Number of sections on a sheet or strip, pcs. | Number of controlled points on a sheet or strip, pcs. | Rejection number |

4-25 26-90 91-150 |

3 13 20 |

1 2 3 |

The tested sheet or strip is considered acceptable if the number of measurement results that do not meet the requirements of Sections 4 and 5 is less than the rejection number given in Table 9.

If unsatisfactory measurement results are obtained on at least one of the controlled sheets or one strip, the batch is rejected.

The manufacturer is allowed to carry out a complete inspection if an unsatisfactory result is obtained.

The manufacturer is allowed to carry out quality control of the surface and dimensions of the sheet during the manufacturing process, provided that the quality of the sheets meets the requirements of this standard.

8

GOST 6235-2020

6.3 For testing for bending, camber and cut obliqueness, four strips are selected from a batch.

6.4 For the spherical dimple extension test, four soft strips of 1.0 and 1.2 mm thickness are selected from the batch.

6.5 To check the chemical composition, four sheets or strips are selected from a batch. The manufacturer is allowed to take a sample from the molten metal to check the chemical composition.

6.6 If unsatisfactory results are obtained from tensile, bending, extrusion and chemical analysis tests, width, length and surface quality control, a repeat test shall be carried out on a double sample taken from the same batch. The results of the repeat test shall be extended to the entire batch.

7 Methods of control and testing

7.1 The quality control of the surface of sheets and strips is carried out using a statistical method that ensures the specified surface quality with a probability of 96%. The surface of sheets and strips is inspected without the use of magnifying devices.

7.2 The thickness of sheets is measured at a distance of at least 100 mm from the apex of the corner and at least 10 mm from the edge of the sheet or strip using a micrometer in accordance with GOST 6507, a caliper in accordance with GOST 166, or a thickness gauge in accordance with GOST 11358.

The dimensions of sheets and strips are checked with a specified probability of 96%. The results of measuring the dimensions of sheets and strips that do not meet the requirements of Tables 1-6 should not differ from those permitted by more than half the tolerance field.

The number of sheets or strips in a batch M, pcs., is calculated using the formula

M = 10 6 · , (1)

where P is the batch weight, kg;

Y - material density, g/cm³;

h - thickness of sheet, strip, mm;

b - sheet, strip width, mm;

l - length of sheet, strip, mm.

The number of controlled areas on a sheet, strip N, pcs., is calculated using the formula

N = , (2)

where l is the length of the sheet, strip, mm;

b - sheet, strip width, mm.

The width and length of sheets are measured using a ruler in accordance with GOST 427 or a tape measure in accordance with GOST 7502.

It is permitted to control the dimensions of sheets and strips at the manufacturing plant by other measuring means that ensure the necessary accuracy. If disagreements arise, control is carried out by statistical control methods.

7.3 For tensile testing, one sample is cut from each selected sheet or strip along the rolling direction. Samples for tensile testing are selected in accordance with GOST 24047.

Tensile tests are carried out according to GOST 1497 on samples of type I or II with an initial calculated sample length l0 = 5.65 mm ( F0 is the initial cross-sectional area of the sample) and a width of 20 mm for sheets and strips with a thickness of 7 mm or less and a width of 30 mm for sheets and strips with a thickness of 8.0 mm or more.

7.4 The crescent shape and obliqueness of the cut are determined according to GOST 26877.

7.5 For the bending test, one sample is cut from each selected strip in the rolling direction. The bending test is carried out in accordance with GOST 14019.

7.6 For the extrusion test, one sample is cut from each selected strip. The extrusion test is carried out in accordance with GOST 10510.

7.7 To determine the chemical composition, one sample is cut from each selected strip or sheet in accordance with GOST 24231. The chemical composition is determined in accordance with GOST 13047.1 - GOST 13047.4, GOST 13047.6, GOST 13047.7, GOST 13047.14, GOST 13047.17, GOST 13047.18, GOST 6689.1 - GOST 6689.22, GOST 6012.

9

GOST 6235-2020

It is permissible to conduct chemical analysis using other accelerated methods that are not inferior in accuracy to those specified.

If disagreements arise in the assessment of the chemical composition, the analysis is carried out in accordance with GOST 13047.1 - GOST 13047.4, GOST 13047.6, GOST 13047.7, GOST 13047.14, GOST 13047.17, GOST 13047.18, GOST 6689.1 - GOST 6689.22, GOST 6012.

7.8 The manufacturer is allowed to use other control methods that ensure the required accuracy.

7.9 Measurement results are rounded according to regulatory documents in force in the territory of the state that adopted the standard*.

8 Packaging, labeling, transportation and storage

8.1 Cold-rolled strips up to and including 2.00 mm thick are packed in bundles. The bundles must be wrapped in paper and protected at the top and bottom with boards or wooden shields, the dimensions of which correspond to the width and length of the bundle, and tied crosswise in at least two places with steel or synthetic tape measuring at least 0.3 × 20 mm or wire with a diameter of at least 2 mm.

Fasten the ends of the wire by twisting at least three turns, and the tape by locking.

Sheets and strips with a thickness of more than 2.00 mm must be packed in packs with one-sided protection by shields according to the pack dimensions, as specified above.

Sheets and strips with a thickness of more than 5.00 mm may not be tied into bundles.

8.2 The gross weight of sheets in a pack must not exceed 80 kg.

By agreement between the consumer and the manufacturer, the weight of the packaging space may exceed 80 kg.

8.3 Sheets and strips are wrapped in paper and packed in dense wooden or lattice boxes of types I-VIII according to GOST 2991 and GOST 10198 or other boxes according to technical documentation with mechanical strength standards according to GOST 26838 and lined inside with waterproof paper.

Hot rolled sheets and strips may not be packaged.

The gross weight of the box must not exceed 500 kg.

Dimensions of boxes - according to GOST 21140 or other technical documentation.

8.4 Cargo items (boxes, packs and individual sheets and strips) are consolidated into transport packages in accordance with GOST 24597.

Fastening means for transport packages - according to GOST 21650.

During mechanized loading and unloading, the weight of a cargo item or transport package must not exceed 1250 kg.

Other methods and means of forming packages according to technical documentation are permitted, taking into account the requirements of GOST 26663, GOST 24597, GOST 21650.

Packaging is carried out on pallets according to GOST 33757 or without pallets using bars at least 50 mm high with strapping in the longitudinal and transverse directions with wire at least 2 mm in diameter or tape at least 0.3 × 20 mm in size. The ends of the wires are fastened by twisting at least five turns, and the tapes are fastened into a lock.

8.5 It is permitted to transport sheets and strips in containers according to GOST 15102, GOST 22225, GOST 20435 and GOST 18477 or according to technical documentation without packing in boxes, paper, synthetic and non-woven materials and without protection with wooden boards. In this case, cardboard must be placed between the rows of packs.

When transported in containers, sheets and strips must be laid and secured in such a way as to prevent their movement in the container. In addition, they must be protected from contamination and mechanical damage.

8.6 At the end of each sheet or strip not tied into bundles, a label must be applied, attached or glued indicating:

- trademark or name and trademark of the manufacturer;

- name of the country of manufacture;

- conventional designation of sheets;

- batch numbers;

- technical control stamp.

* ST SEV 543-77 "Numbers. Rules for recording and rounding" is in effect.

10

GOST 6235-2020

When shipping sheets and strips bundled into packs, the above data is placed on a label attached to the pack or glued to the top strip or top sheet of the pack.

8.7 Each cargo space, each box or container must be provided with, enclosed, or attached packing lists containing:

- trademark or name and trademark of the manufacturer;

- name of the country of manufacture;

- conventional designation of sheets;

- batch number;

- net weight;

- gross weight;

- packer number.

8.8 Transport marking - according to GOST 14192 with the application of the handling sign "Keep away from moisture".

When transporting goods by air, labels must be made of wood or metal and attached on both sides.

8.9 The following should be used as packaging means, materials and fastening means:

- paper according to GOST 8273, GOST 8828;

- corrugated cardboard according to GOST 7376;

- cardboard according to GOST 7933;

- synthetic and non-woven materials according to technical documentation;

- boards and panels according to technical documentation;

- tapes according to GOST 3560;

- wire according to GOST 3282;

- synthetic tape according to technical documentation.

It is permissible to use other types of packaging materials that are not inferior in strength to those listed above, as well as other types and methods of packaging that ensure the preservation of product quality.

8.10 Packaging of sheets and strips intended for shipment to regions of the Far North and equivalent localities - in accordance with GOST 15846 for the group "Metals and metal products".

8.11 Sheets and strips are transported by all types of transport in covered vehicles in accordance with the transportation rules and conditions for loading and securing cargo in force for the given type of transport.

8.12 Sheets and strips for sea transportation are transported in accordance with GOST 26653.

8.13 Sheets and strips must be stored in closed rooms, in boxes or on shelves, pallets and racks. During storage and transportation, sheets and strips must be protected from mechanical damage, exposure to moisture and active chemicals.

The consumer must keep the sheets and strips in the manufacturer's packaging in the warehouse for at least two days to equalize the temperature of the sheets and strips with the room temperature. After this period, they must be unpacked.

If the specified transportation and storage conditions are met, the consumer properties of sheets and strips do not change.

11

GOST 6235-2020

Appendix A

(informative)

Thickness and theoretical weight of 1 m² of hot rolled sheets and hot rolled

and cold rolled strips

Table A.1

| Sheet thickness, strip, mm | Theoretical weight of 1 m², sheet, strip, kg | Sheet thickness, strip, mm | Theoretical weight of 1 m², sheet, strip, kg |

1.0 1,2 1.5 1.8 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 |

8.90 10.68 13.35 16.02 17.80 22.25 26.70 31.15 35.60 40.05 44.50 48.95 53.40 57.85 |

7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.0 15.0 16.0 17.0 18.0 19.0 20.0 |

62.30 71.20 80.10 89,00 97.90 106.80 115.70 124.60 133.50 142.40 151.30 160.20 169.10 178,00 |

| Note: When calculating the theoretical mass of sheets and strips, the density of nickel is taken to be 8.9 g/ cm3 . | |||

UDC 669.3.413;418:2:006.354 ISS 77.150.60

Key words: nickel sheets and strips, cold-rolled, hot-rolled, assortment, technical requirements, control, acceptance rules