TU 07 14E 097 80 A

TECHNICAL SPECIFICATIONS

FORGED AND ROLLED RODS

MADE OF STEEL AND IRON-NICKEL BASED ALLOY

FOR NUCLEAR POWER PLANT FITTINGS

TU 07 14E 097/80/A

Developed by: Kamil Salzmann, 09/2014

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

Approval sheet: TU 07 14E 097/80/A

I APPROVE

Main designer

Martin Klimša

"29" 09 2014

| AGREED (suppliers) |

AGREED

Deputy General Director -

Director of the Institute of Materials Science

OJSC NPO "TsNIITMASH"

V.N. Skorobogatykh

letter No. 04/23-4149BC

from "14" August 2014

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

CONTENT

1 Assortment 4

2 Technical requirements 4

3 Acceptance Rules 6

4 Test methods 9

5 Documentation, marking 10

Appendix A Maximum Permissible Depth of Surface Defects

hot rolled rods 15

Change Registration Sheet 16

| TU 07 14E 097/80/A | ||||||||||

| Change | Sheet | Doc. No. | Subp. | Date | ||||||

| Developer. | K. Salzmann | 09.2014 | FORGED AND ROLLED RODSMADE OF STEEL AND IRON-NICKEL ALLOYBASISFOR NUCLEAR POWER PLANT FITTINGS |

Lit. | Sheet | Sheets | ||||

| Prov. | 1 | 2 | ||||||||

| Head of CO | ||||||||||

| N. counter. | ||||||||||

| Approved. | M. Klimsha | 09.2014 | ||||||||

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

| Reference No. | First Applicant |

These technical conditions apply to forged and rolled rods made of steel and iron-nickel alloys specified in Table 2. The rods are intended for the manufacture of cold mechanically processed parts of NPP fittings related to equipment of groups B and C according to PNAE G-7-008-89.

The technical conditions were developed taking into account the requirements of NP-068-05.

1. ASSORTMENT

The assortment of rods by size must correspond to Table 3. Deviations in the diameter of round rods and in the size under the key of hexagonal rods are indicated in Table 3.

Requirements beyond the relevant standards must be agreed upon when ordering.

2. TECHNICAL REQUIREMENTS

2.1 Surface condition

2.1.1 The rods are supplied with an untreated surface (after pressure treatment) or in a treated condition (after stripping). The requirement for the surface condition must be specified in the order.

2.1.2 The following requirements for the surface quality of the rods are established.

2.1.2.1 Hot rolled and forged bars.

The surface of forged rods shall not have cracks, films, or laps with a depth exceeding 80% of the one-sided processing allowance. The requirements for the maximum permissible depth of surface defects of rolled rods are established in Appendix A. Roughness, dents from rolled or forged scale, irregularities from tools, imprints, scratches and shallow scratches are allowed without correction. A decarburized surface layer is allowed. Its maximum permissible depth shall not be more than:

- for forged bars - 80% one-sided allowance for processing

- for rolled bars - in accordance with Appendix A.

2.1.2.2 Rods after pressure processing (drawing) in a cold state.

The surface is matte, with traces of heat treatment or etching, shot blasting and straightening. Surface defects are not allowed and must be cleaned to a depth not exceeding the maximum dimensions specified in Appendix A.

2.1.2.3 Rods with cleaned surface.

Surface defects are not allowed and must be cleaned to a depth not exceeding the maximum deviations. Tool marks are allowed. Correction of defects by sampling and welding of samples is not allowed.

2.2 Method of steel production

High-alloy steels are produced in a basic electric furnace, carbon and alloy steels in an open-hearth or electric furnace.

2.3 Chemical composition

The chemical composition of the rods based on the results of the ladle sample analysis must meet the requirements of Table 4. In finished products, subject to compliance with the other requirements of the technical specifications, deviations from the chemical composition given in Table 4 are allowed.

| TU 07 14E 097/80/A | Sheet | |||||

| 4 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

2.4 Heat treatment

The rods are supplied in a heat-treated condition. The type of heat treatment is given in Table 5. The type of heat treatment is specified in the order and is designated in the metal product certificate by the words - according to Table 5.

2.5 Brinell hardness

The manufacturer guarantees a minimum difference in hardness of 12 HB for the KhNZ5VT alloy between the state after austenitization (KhNZ5VT, PS-147) and after austenitization and aging (KhNZ5VT, PS-353). Note: PS stands for "strength category" (see Table 5).

2.6 Mechanical properties

The mechanical properties of bars at room temperature and at 350°C in a heat-treated condition, determined on longitudinal samples, must meet the requirements of Table 5.

2.7 Critical brittleness temperature T KO

At the customer's request, rods made of steel grades 12 020.1 (up to and including 100 mm in size) and 15 320.9 are tested for a critical brittleness temperature of minus 10°C (T KO ≤ -10°C).

2.8 Corrosion properties

Rods made of steel grades 14X17H2, 08X18H10T and alloy ХН35ВТ must be resistant to intercrystalline corrosion.

2.9 Contamination of metal with non-metallic inclusions

2.9.1 Contamination with non-metallic inclusions of rods made of steel grade 08X18N10T is guaranteed to be no higher than the following values:

| inclusion type: | OS | FROM | CX | SP | SN | WITH | NS | NT |

| max. score according to GOST 1778: | 2 | 2 | 2 | 2 | 2 | 2 | 4 | 4 |

The average score may be exceeded by 0.5 points for no more than two types of inclusions (except for inclusions of the NS and NT types).

2.9.2 Contamination of rods made of KhNZ5VT alloy with line carbonitrides and point carbonitrides is monitored at the customer's request.

2.10 Delta ferrite content

At the customer's request, the ferrite phase of 08X18H10T steel rods must be tested. In cast metal, the ferrite phase content, determined by the volumetric magnetic method, must be 0.3-8.0%.

2.11 Macrostructure

On the transverse etched surfaces of macrosections there should be no visible to the naked eye cavities, delaminations, cracks, porosity, large non-metallic inclusions and flakes. In the macrostructure of corrosion-resistant steels, the central porosity, point heterogeneity, liquation square and general spotty liquation should not exceed 2 points, and the marginal spotty and shrinkage liquation - 1 point on the scale of GOST 10243.

2.12 Ultrasonic testing

Rolled rods over 20 mm in size are subject to ultrasonic testing and must meet the requirements for rods of quality class 2 according to GOST

| TU 07 14E 097/80/A | Sheet | |||||

| 5 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

21120-75. Forged rods during ultrasonic testing must meet the requirements established for forgings of group 4n of GOST 24507. Before ultrasonic testing, the rods must be subjected to mechanical processing by stripping or grinding.

3. ACCEPTANCE RULES

3.1 Acceptance

Control and acceptance are carried out by the supplier's quality control department in accordance with the requirements of the order and these TU. The customer has the right to participate in control and acceptance at the supplier's plant. The rods are presented for acceptance in batches.

3.2 Batch of rods

A batch of rods consists of rods from the same melt, of the same size, heat-treated as follows:

a) One heat treatment mode (normalization or austenization, in the case of heat treatment in a continuous furnace;

b) in one batch in the case of heat treatment in a chamber furnace (for other types of heat treatment).

3.3 Sampling and scope of acceptance testing

Sampling and acceptance testing shall be carried out after all heating operations performed during pressure and heat treatment have been completed as follows:

From each swimsuit:

a) Determination of chemical composition: on one sample from the melt-ladle.

b) Determination of delta-ferrite content in 08X18H10T steel: on two cast samples from

swimming trunks.

c) Control of non-metallic inclusions in rods made of 08X18H10T steel and KhNZ5VT alloy - by 6

samples selected in accordance with GOST 1778.

d) Control of the macrostructure of rods larger than 20 mm: at the end of one rod from

melting, or on a macrosection taken from a rod. It is permissible to distribute the results

macrostructures and rods from the same melt with smaller dimensions.

From each party:

a) Tensile test at 20°C: on two specimens taken from each of the two

rods from the batch.

b) Tensile test at 350°C: on two specimens taken from each of the two

rods from the batch.

c) Impact bending test at room temperature on three specimens, from each of

two rods from the batch.

d) The hardness control of rods is performed in the following volume:

- From steel 12 020.1, 15 320.9, 14X17H2 and alloy KhNZ5VT - 10% of the batch;

- from steel 15 236.3 - 5% of the batch;

- the hardness of rods made of 08X18H10T steel is not controlled.

d) confirmation of the critical brittleness temperature is performed on six samples of three

sample at minus 10°C and at 20°C.

Notes:

1. Tensile tests at 20°C and 350°C are carried out on bars of all steel grades.

Impact bending tests are carried out only on bars made of steel,

| TU 07 14E 097/80/A | Sheet | |||||

| 6 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

which in Table 5 are standardized impact toughness or critical brittleness temperature T KO .

2. The results of mechanical tests of one size of rods may not be extended to rods

other sizes.

3. If the critical brittleness temperature is confirmed, the impact toughness is not controlled.

4. Intercrystalline corrosion testing is carried out on rods made of steel grades 14X17H2, 08X18H10T and

alloy XH35BT. For rods made of steel 14X17H2 - on 4 samples, of which two samples are

control, for rods made of steel grades 08X18H10T and ХН35BT - on two samples. Samples for testing

for resistance to MCC, samples are taken from the axial part in the longitudinal direction in accordance with GOST 6032.

Each rod undergoes the following types of control:

a) measuring,

b) visual,

c) ultrasonic.

3.4 Selection of samples for mechanical testing

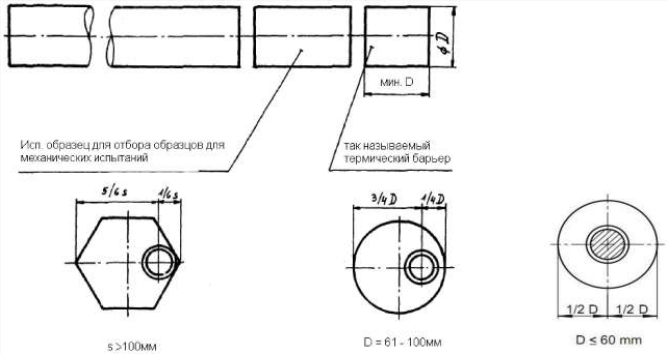

Sampling for the production of specimens intended for tensile and impact bending tests and confirmation of the critical brittleness temperature is carried out after heat treatment from one bar from the batch. Specimens for mechanical testing are taken in the longitudinal direction, and for bars of the following dimensions:

a) up to and including 60 mm: the axis of the test specimen lies in the middle of the rod,

b) 61-100 mm inclusive: the axis of the test specimen lies at a distance of the diameter or

diagonals from the surface of the rod,

c) over 100 mm: the axis of the test specimen lies at a distance of the diameter or diagonal

from the surface of the rod.

For rods made of 15 320.9 and 14X17N2 steel, samples are taken at a distance of one diameter or key hole from the end of the rod (see Fig. 1).

Fig.1

3.5 Methodology for confirming the critical brittleness temperature T KO

Confirmation (determination) of the critical temperature is carried out in accordance with PNAE G-7-002-86. The critical brittleness temperature (T KO ≤ -10°C) is confirmed by the impact toughness value determined in accordance with ČSN ISO 148-1 on six samples (standard sample type with V concentrator) at temperatures of: minus 10

| TU 07 14E 097/80/A | Sheet | |||||

| 7 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

°C and 20°C. The arithmetic mean of the test results of three samples tested at one of the specified temperatures, depending on the yield strength determined for the controlled batch, and the proportion of the viscous component in the fracture of impact samples destroyed at 20°C must correspond to Table 1.

TABLE 1 - VALUES FOR DETERMINING THE CRITICAL BRITTLE TEMPERATURE

Yield strength σ 0.2 , N/ mm2 (MPa) |

Test temperature, °C | |||

| Minus 10 | 20 | |||

| Impact strength, J/ cm2 | The proportion of the viscous component in fracture, % | |||

| not less than | ||||

| up to 304 incl. | 29 | 44 | 50 | |

| St. 304 to 402 inclusive. | 39 | 59 | ||

| St. 402 to 549 incl. | 49 | 74 | ||

| St. 549 to 687 inclusive. | 59 | 89 | ||

| St. 687 | - | 59 | ||

A decrease in impact strength is permitted for one of the samples, but not more than 70% of the value specified in Table 1, while the arithmetic mean value of impact strength must be no less than that established in Table 1.

If one of the samples is found to be less than 50%, three additional samples are tested; the critical brittleness temperature will be confirmed if the proportion of the viscous component is not lower than 50% in all additionally tested samples.

3.6 Retesting

In case of unsatisfactory results of individual tests, repeated tests are conducted for the type of tests for which unsatisfactory results were obtained. Repeated tests are conducted on double the number of samples of the type of tests for which unsatisfactory results were obtained. In case of unsatisfactory results of repeated tests, repeated heat treatment is allowed on at least one sample and the rods are presented for acceptance again. Heat treatment can be repeated no more than twice. The number of temperings and stabilizing anneals is not limited. If unsatisfactory results are obtained even after repeated heat treatment, the batch of rods is rejected.

3.7 Additional tests

If some of the tests do not meet the requirements of these TU due to the occurrence of internal defects in the sample, which are not allowed according to these TU and which can be detected in the sample only during or after the test, then the test is considered invalid. In this case, the sample is replaced with a new sample and an additional test is carried out. These tests are not considered repeated tests.

| TU 07 14E 097/80/A | Sheet | |||||

| 8 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

4. TEST METHODS

4.1 Determination of chemical composition

The chemical composition of the rods is determined methodically according to GOST 18895-97 and GOST R 54153-2010. The arbitration methods for determining the chemical composition are the methods of analysis established by the following interstate standards: GOST 12344, GOST 12345, GOST 12346, GOST 12347, GOST 12348, GOST 12350, GOST 12351, GOST 12352, GOST 12353, GOST 12354, GOST 12355, GOST 12356, GOST 12357, GOST 12358, GOST 12359, and GOST 18895, GOST R 54153, GOST 22536.0 - GOST 22536.10, GOST 22536.12.

4.2 Tensile tests

Tensile tests at room temperature are carried out in accordance with ČSN EN ISO 6892-1, at 350°C in accordance with ČSN EN ISO 6892-2. Tensile tests are carried out on five-fold samples with a diameter of d 0 = 10 mm. It is permissible to carry out tests on a sample with a diameter of d 0 = 8 mm or d 0 = 6 mm.

4.3 Impact bending test

Impact bending tests at room temperature and at minus 10°C are carried out in accordance with ČSN ISO 148-1 on standard types of samples with a V concentrator. Evaluation of the proportion of ductile fracture FA in the fracture of samples - according to GOST 4543.

4.4 Brinell hardness testing

Brinell hardness testing is carried out in accordance with ČSN EN ISO 6506-1.

4.5 Control of non-metallic inclusions

Non-metallic inclusions are assessed in rods made of 08Kh18N10T steel and KhN35VT alloy using the Ш1 method in accordance with GOST 1778.

4.6 Determination of ferrite phase content

Determination of the ferrite phase content in rods made of 08Kh18N10T steel is carried out using the volumetric magnetic method according to RMD 2730.300.08 (Ferritometer type FC-2).

4.7 Intergranular corrosion test

The resistance of 14X17H2, 08X18H10T and KhN35VT steels to intercrystalline corrosion is tested using the AMU method according to GOST 6032. Before testing, samples of 08X18H10T and KhN35VT steels are subjected to provocative heating at 650°C ± 10°C (1 hour) in air.

4.8 Macrostructure Control

Macrostructure control is carried out over the entire cross-section of the rods. The controlled surface must be processed with a roughness of at least R a 1.6 and etched. The etching mode is in accordance with the manufacturer's methodology. Control is carried out visually, with the naked eye.

4.9 Control of shape, size and surface quality

The shape and dimensions are controlled using measuring instruments. Surface quality control is carried out visually, with the naked eye.

4.10 Ultrasonic testing

Ultrasonic testing of rolled bars is carried out in accordance with GOST 21120, forged bars - GOST 24507. Defective areas are marked in red, subtracted from the total weight and counted towards the scrap price.

| TU 07 14E 097/80/A | Sheet | |||||

| 9 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

5. DOCUMENTATION, MARKING

5.1 Marking and delivery

5.1.1 Rods made of steel grades 14X17H2, 08X18N10T and alloy KhN35VT with a size of less than 20 mm, and of steel grades 12 020.1, 15 236.3 and 15 320.9 with a size of less than 35 mm are not marked separately. Rods are supplied in packs. A metal label is attached to each pack, on which the following data is legibly indicated in indelible paint:

- manufacturer's trademark,

- steel grade, alloy (type of heat treatment),

- melt number,

- size.

5.1.2 Each stainless steel rod with a size of 20 mm or more, as well as carbon and alloy steel rod with a size of 35 mm or more, shall be marked at one end with the following data:

- manufacturer's trademark,

- grade and condition of steel (alloy),

- melt number.

5.1.3 It is allowed:

- when specifying the melt number, provide the last three digits of the melt number,

- mark the steel grade using the supplier's plant designation.

The marking must be deciphered in the certificate.

5.1.4 The rods are designated by color as follows:

steel 12 020.1 green - white - orange

steel 15 236.3 white - blue - brown

steel 15 320.9 white - brown - purple

steel 14Х17Н2 green

steel 08Х18Н10Т PS-157 white

steel 08Х18Н10Т PS-167 white - yellow

steel ХН35ВТ PS-353 red

steel ХН35ВТ PS-147 brown

5.2 Accompanying documentation

For each batch of rods that meets the requirements of the order and the technical specifications, a certificate must be issued with the following data:

- steel grade (alloy),

- type of heat treatment of rods (in accordance with the type of heat treatment specified in Table 5),

- melt number,

- the size and weight of each batch of rod steel,

- results of all tests prescribed in the order and these specifications,

- confirmation that the batch of rods meets the requirements of the order and the technical specifications.

The metal product certificate must be signed by the supplier's quality control department (QCD). The certificate is issued and supplied in the language version according to the requirements specified in the order.

5.2.1 Data for placing an order

The order must contain the following basic information:

a) cross-section shape (name of rods - round, hexagonal, etc.),

b) dimensions and tolerance (indicate tolerance by the number of the dimensional standard in Appendix A with additional numbers),

| TU 07 14E 097/80/A | Sheet | |||||

| 10 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

c) production technology (execution - rolled, forged, etc.),

d) surface quality (press-treated, cleaned or polished),

d) method of subsequent processing at the customer's (purpose of use - only for processing),

f) steel grade and heat treatment,

g) name of the technical specifications,

c) quantity (in kg, or for exact lengths also in pieces),

i) decoding of the color of the rods (standard according to Art. 5.1.4),

k) indication of additional tests: confirmation of the critical brittleness temperature and control of the ferrite phase,

l) the minimum applicable length of the rod can be specified in the order,

m) or other requirements (length of rods, packaging, preservation, type of transport, customer participation during acceptance, etc.).

TABLE 2 - STEEL (ALLOY) GRADES AND TYPE OF BARS DELIVERY

| p/p | Steel (alloy) group | Steel grade(alloy) |

Type of supply of rods |

| 1 | Carbon | 12 020.1 | hot rolled |

| forged | |||

| 2 | Alloyed | 15 236.3 | cold drawn (with subsequent heat treatment) |

| hot rolled | |||

| forged | |||

| 3 | 15 320.9 | hot rolled | |

| forged | |||

| 4 | High alloy (stainless steel) |

14Х17Н2 | hot rolled |

| forged | |||

| 5 | 08Х18Н10Т | hot rolled | |

| forged | |||

| 6 | Iron-nickel alloy basis |

ХН35ВТ | hot rolled |

| forged |

| TU 07 14E 097/80/A | Sheet | |||||

| 11 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

TABLE 3 - MAXIMUM BAR SIZE AND ALLOWABLE DEVIATIONS

Steel grade (alloy) |

12 020.1 | 15 236.3 | 15 320.9 | 14X17H2 | 08X18H10T (PS-167) |

XH35BT (PS-353) |

XH35BT (PS-147) | |||

Maximum size, mm |

200 | 80 | 80 | 120 | 180 | 80 | 125 | |||

| Permissible deviation (mm) | hot rolled (forged) | Circular cross-section | up to 15 | ± 0.4 | ||||||

| 16-25 | ± 0.5 | |||||||||

| 26-35 | ± 0.6 | |||||||||

| 36-50 | ± 0.8 | |||||||||

| 52-80 | ± 1.0 | |||||||||

| 85-100 | ± 1.3 | - | - | ± 1.3 | ± 1.3 | - | ± 1.3 | |||

| 105-120 | ± 1.5 | - | - | ± 1.5 | ± 1.5 | - | ± 1.5 | |||

| 125-160 | ± 2.0 | - | - | - | ± 2.0 | - | ± 2.0 | |||

| 165-200 | ± 2.5 | - | - | - | ± 2.5 | - | - | |||

| 6-tigran | up to 15 | ± 0.4 | ± 0.4 | - | - | - | - | ± 0.4 | ||

| 16-24 | ± 0.5 | ± 0.5 | - | - | - | - | ± 0.5 | |||

| 25-34 | ± 0.6 | ± 0.6 | - | - | - | - | ± 0.6 | |||

| 35-48 | ± 0.8 | ± 0.8 | - | - | - | - | ± 0.8 | |||

| 52-80 | ± 1.0 | ± 1.0 | - | - | - | - | ± 1.0 | |||

| Permissible deviation of cold drawn bars | ||||||||||

| up to 80 | - | h13 | - | - | - | - | - | |||

| TU 07 14E 097/80/A | Sheet | |||||

| 12 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

TABLE 4 - CHEMICAL COMPOSITION AND PRODUCTION METHOD OF STEEL

| Steel grade | 12 020.1 | 15 236.3 | 15 320.9 | 14X17H2 | 08X18H10T | XH35BT | |

| Production method | open-hearth steel or electric steel | open-hearth steel or electric steel | open-hearth steel or electric steel | Electrosteel | Electrosteel | Electrosteel | |

| Mass fraction of elements in % | C | 0.13-0.20 ±0.01 | 0.17-0.27 ±0.02 | 0.20-0.28 ±0.02 | 0.11-0.17 ±0.01 | max 0.080 | max 0.12 +0.01 |

| Mn | 0.60- | 0.30- | 0.50- | max 0.800 | max 2.00 | 1.0-2.0 | |

| Si | 0.17- | 0.15- | 0.17-0.37 ±0.05 | max 0.800 | max 0.800 | max 0.600 | |

| P | max 0.04 | max 0.040 | max 0.040 | max 0.030 | max 0.035 | max 0.030 | |

| S | max 0.04 | max 0.040 | max 0.040 | max 0.025 | max 0.020 | max 0.020 | |

| Cr | max 0.30 | 1,20- | 1.10-1.40 ±0.10 | 16.0-18.0 | 17.0-19.0 | 14.0-16.0 | |

| Ni | max 0.35 | - | - | 1.5-2.5 | 9.0-11.0 | 34.0-38.0 | |

| Mo | - | 0.25-0.50 ±0.05 | 0.55-0.75 ±0.01 | - | - | - | |

| V | - | 0.45-0.65 ±0.05 | 0.15- | - | - | - | |

| W | - | - | - | - | - | 2.8-3.5 ±0.05 | |

| You | - | - | - | - | 5xC-0.7 ±0.05 | 1.1-1.5 ±0.1 | |

| Cu | max 0.30 | - | - | - | max 0.25 | - | |

| Cr+Cu+Ni | - | - | - | - | - | - | |

| Co | - | - | - | - | max 0.070 | - | |

| N | - | - | - | max 0.050 | max 0.050 | - | |

| The chemical composition complies with the standard | CHSN 41 2020 | CHSN 41 5236 | CHSN 41 5320 | - | - | - | |

Note: At the customer's request, the cobalt content in 08X18N10T steel is allowed to be no more than 0.05%.

| TU 07 14E 097/80/A | Sheet | |||||

| 13 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

TABLE 5 - HEAT TREATMENT AND MECHANICAL PROPERTIES OF RODS

| Steel grade | 12 020.1 | 15 236.3 | 15 320.9 | 14Х17Н2 | 08Х18Н10Т(PS-167) 1) |

ХН35ВТ(PS-353) 1) |

ХН35ВТ(PS-147) 1), 2) | ||||

| Heat treatment method | Normalization | Softening annealing |

Hardening and vacation |

Hardening and vacation |

Austenitization, Austenitization with stabilization |

Austenitization and aging |

Austenitization | ||||

| Size | mm | up to 100 | 101-200 | up to 80 | up to 80 | up to 120 | up to 180 | up to 80 | up to 125 | ||

| Hardness of HB after heat treatment | NV | max 163 | max 200 | 212-270 | 240-300 | - | - | - | |||

Mechanical properties in longitudinal direction test at temperature 3) |

20°C | R m | N/ mm2 | 390 | 390 | - | 700-883 | 785-981 | 480 | 686-1070 | - |

| R e , R p0,2 | N/ mm2 | 225 | 205 | 400 | 588 | 588 | 205 | 392 | 215 | ||

| A 5 | % | 26 | 24 | - | 15 | 14 | 35 | 15 | - | ||

| Z | % | 55 | 50 | - | 45 | 45 | 50 | 20 | - | ||

| 350°C | R m | N/ mm2 | 300 | - | - | 640 | - | 333 | 586 | - | |

| R p0,2 | N/ mm2 | 130 | 113 | 300 | 392 | 430 | 167 | 353 | 147 | ||

| A 5 | % | 25 | - | - | 13 | - | 25 | 15 | - | ||

| Z | % | 50 | - | - | 40 | - | 40 | 15 | - | ||

| Impact strength 3) | 20°C | KCU 2 | J/ cm2 | - | - | - | - | 49 | - | - | - |

| KCU 3 | J/ cm2 | - | - | - | - | - | - | - | - | ||

Tests on critical temperature of the T KO according to Art. 3.5 3) |

-10°C | KCV | J/ cm2 | 4) | 4) | 4) | 4) | ||||

| 20°C | KCV | J/ cm2 | 4) | 4) | 4) | 4) | |||||

| FA | % | 4) | 4) | 4) | 4) | ||||||

Note: 1) PS stands for "strength category", the numbers after PS stand for the yield strength R p0.2 at 350°C in N/mm²

2) reference

3) if the range of values (or max. value) is not specified, then all values are minimum

4) the values for determining the critical brittleness temperature are given in Table 1 (depending on the yield strength R e , R p0,2 )

| TU 07 14E 097/80/A | Sheet | |||||

| 14 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

APPENDIX A

MAXIMUM ALLOWABLE DEPTH OF SURFACE DEFECTS IN HOT-ROLLED RODS

Rod size (mm) |

from | - | 16 | 26 | 51 | 81 | 101 | 121 | 161 |

| to | 15 | 25 | 50 | 80 | 100 | 120 | 160 | 200 | |

Maximum depth defect (mm) |

0.6 | 1.0 | 1,2 | 1.5 | 2.0 | 2.4 | 3.2 | 4.0 | |

| TU 07 14E 097/80/A | Sheet | |||||

| 15 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |

Change Registration Sheet

| Change | Sheet (page) numbers | Total sheets (pages) in doc. |

Doc. No. | Incoming No. accompany- long-term document and date |

Subp. | Date | |||

changed- nyh |

replace- undefined |

new | annulled bathrooms | ||||||

| TU 07 14E 097/80/A | Sheet | |||||

| 16 | ||||||

| Change | Sheet | Doc. No. | Subp. | Date |

| Inv. No. | Sub. and date | Exchange inv. No. | Inv. No. duplicate. | Sub. and date |

| 011/2015-TY | 10/12/2015 |